Join Callaway Rewards and Earn 3X Bonus Points On All Purchases + Free Shipping!

Sign Up for 3X Reward Points + Free Shipping!

Free Shipping & Free Returns On All Orders! View Details

Added to Cart!

Shop Our Featured Products

Shop By Family

Choose the Driver, Fairway Wood, Hybrid, or Iron Set that Works Best for Your Game.

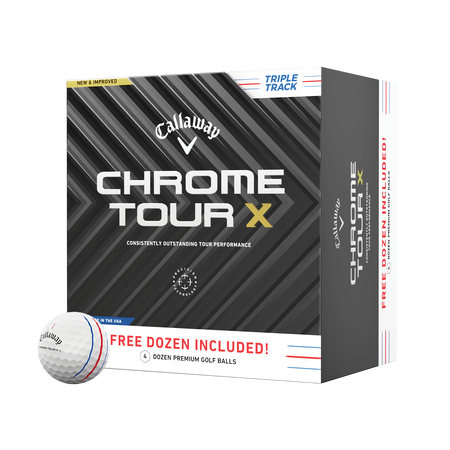

Strike Gold With The Chrome Family

Now get 4 dozen for the price of 3 on Chrome Tour, Chrome Tour X, and Chrome Soft balls.

Shop Now

Big Bertha Irons

The perfect irons for the middle-to-high-handicapper. These irons help the ball get in the air, go far and make the game more fun and enjoyable.

Shop Now

Shop Performance Gear

Shop 2024 new arrivals, the latest and greatest in golf bags, headwear, gloves and more!

Rapsodo Mobile Launch Monitors

Revolutionize your golf game with Rapsodo Mobile Launch Monitors - the ultimate tools for any golfer that wants to get better and have fun doing it. Unlock unparalleled insights and data, and take your practice sessions to the next level with Golf's top rated personal launch monitors.

Shop Now

Golf Shoes

Tee off in style and comfort with men's and women's golf shoes. Find your perfect fit and experience the fusion of superior comfort and outstanding performance.

Shop Now

Shop Golf Balls

Shop Chrome Tour, Chrome Soft, ERC Soft, Supersoft, and more.

Shop Complete Sets

Complete sets are great for beginner golfers, juniors, and those looking for a quality ‘all in one’ set. You will have a complete matching set right out of the box.